Self-supporting form for arch bridges

Details largest bridge:

- Width on top 10m, width at the base 20,8m

- Span 20,3m, arch length 25,6m

Bridge pier formwork

This large infrastructure job included:

- 4 bridges

- 13 viaducts

- 5 tunnels

Specifications of the piers:

-

- Length up to 21,5m

- Width tapered 75cm to 134cm

- Height 6,425m

Formwork for tall viaduct piers

Details piers:

- Tall piles in a hyperstatic structure

- Modular height from 7m to 17,25m

- Thickness adjustable per 100mm from 400mm to 800mm

- Self-compacting high performance concrete

Details formwork:

- No tie-bars through the elements

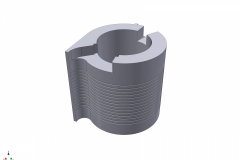

- Adjustable thickness with saw-tooth coupling

- Hydraulic adjustment of the vertical parts

- Connections between formwork and grade beam

- Box-outs to make chamfered piles

- Maximum concrete pressure 420kN/m²

- Fair-faced finish: no joints, no grout loss, triangular chamfers

- All levels equipped with working platforms

- Wind impact engineering on all configurations

- Foundation frames for positioning of anchors and box-outs

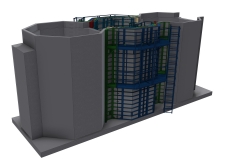

Quai wall formwork

Sea side quay

- Total length 1200m, straight

- Length per phase 23m

- Number of phases 53

- Height wall land side 7000mm

- Height foot 1500mm / 1750mm

- Thickness wall 2160mm / 2800mm

- 2 sets of formwork

- Alternating

- 1 set for even numbers

- 1 set for uneven numbers

- Track width 22,65m

- Height gantry crane 13m

- Weight per set approx. 100T

Land side quay

- Total length 1100m, U-form

- Length per phase 29,39m

- Number of phases 37

- Height wall land side 7000mm

- Height wall water side 2260mm

- Thickness wall 2160mm / 2800mm

- 1 sets of formwork

- Track width 8,1m

- Height gantry crane 15,23m

- Weight per set approx. 100T

Pier formwork

- Columns with a height of 9,2m

- Ground section: 3,3m x 1,15m

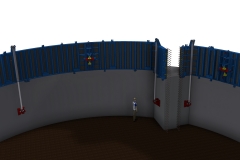

Hydraulic climbing circular wall formwork

- Inner diameter 20m, wall thickness 800mm, height 26,5m

- Full circumference inside and outside formwork, poured in one go, height 2m

- Partition wall between dry and wet part of the tank is poured afterwards

- A 1m starter is cast on both ends of the partition wall in phase 1

Formwork for octagonal tanks

Octagonal reactor pits for a drink water production facility

A series of 6 x 5 linked together octagonal tanks:

- 2 outer octagons of which 1 sits against an existing wall

- 3 inner octagons

- Height 6430mm, wall thickness 350mm,

- external faces 2030mm wide, internal faces 1740mm wide

- 1 complete set of formwork + 1 extra inside core

- Inner formwork consisting of 7 corner panels and 1 striking panel

Adjustable formwork and climbing system for twisted walls

The new County Hall in Antwerp is a building with 8 completely twisted levels.

The outside walls of these floors lean back- or forwards. All concrete used is white and the inside of the building needs to be fair-faced. For this purpose, we designed and manufactured a full steel adjustable and twistable formwork without tie-bars through the wall and of which the inside panels have a stainless-steel facing, in order to avoid rust stains.

Technical specifications

- 12 internal panels 720cmm x 410cm

- 4 external panels 720cm x 410cm

- 12 pneumatic vibrators per internal panel

- 3 straight corners

- 4 adjustable twisted corners

- 16 adjustable window forms

- All cut to measure plywood for the windows of the 8 twisted levels

- 2 set-up frames for the window forms

- Crane lifting hook for the panels

- Crane lifting hook for the window forms

- Adjustable climbing frames, 3m and 3,5m wide

Formwork for curved walls with relief

For the Mons railway station, Construx supplies a one-off full steel circular shuttering system with round relief

Both 2 main circular cores and their connecting walls need to be poured on-site. Almost all walls are round, some of which are even round in both directions. All formwork is full steel: steel frame with steel sheeting.

Precast moulds · on-site formwork and scaffolding for viaduct piers

All piers have the same cross-sectional base and rectangular top

Seen the height of the piers varies from 4m to 14m, all vertical ribs have a different inclination.

The 1st stage consists of a viaduct with 34 high piers, poured on-site, after which 2 precast 80T heads are positioned on hydraulic scaffolds. The connection is poured afterwards.

The 2nd stage consists of a viaduct with 14 lower piers. The precast heads are positioned onto a hydraulic scaffold under which the piers are poured.

- Adjustable modular pier formwork

- Hydraulically tiltable and moveable pier head moulds

- Transport yokes for truck and barge

- Internal rebar supports

- External modular rebar scaffolds

- Hydraulic support scaffolds

- Connection form

- Hydraulic frames to hold the heads